Although sound cannot be completely blocked, it can be greatly reduced. Using materials to block sound is referred to as ‘soundproofing’. An individual or business may need soundproofing to control unwanted noise, such as motor engines, external noise from busy roads or neighbours, or noise from air conditioning units, for example.

There are many different materials that can be used to block sound, however some may prove more suitable or effective than others. It all depends on the source of the noise and how loud the unwanted noise is.

How does material block sound?

Sound is not something that we can see – so how do we contain it? Sound is a form of energy that travels from a source and during this process, it causes vibrations whenever it hits air and any objects in its path. These sound waves then reach your ears and stimulate the brain.

In order to reduce this sound, we have to interrupt this chain of events. We can do this by using material as a barrier. There are a number of materials that can be used to do this. You cannot use just any material to reduce sound. A soundproof material must provide these basic functions:

- Sound isolation

- Sound absorption

- Vibration

- Isolation

- Vibration absorption

How do you know if a material is soundproof?

A material must also have a number of particular characteristics in order to be suitable for soundproofing. Firstly, it must be dense. This is a measure of how packed together the molecules of a material are. Sound waves find dense material more difficult to pass through and will usually become absorbed as they try and do so.

A material must also have flow resistivity. This is the most important characteristic of sound absorbers. Flow resistivity is the airflow resistance within a unit of thickness. It reflects the air permeability through porous materials. The higher the airflow resistivity, the less air permeability there is and the more sound will be absorbed.

Cell size is also important. The cell size of the material must be smaller than the wavelength of the sound it is designed to absorb or block. It’s also important to take the cell arrangement into account. A more open cell arrangement is better for absorption and a closed-cell arrangement is better for blocking sound.

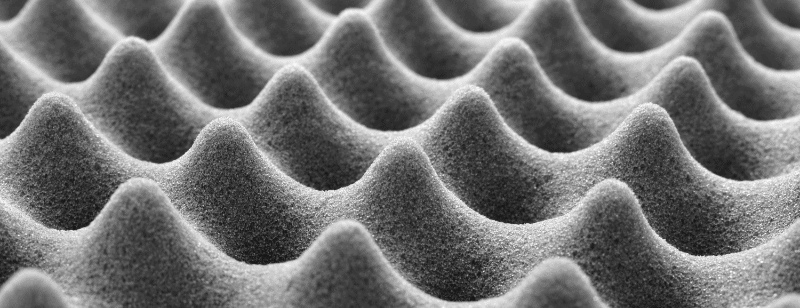

It’s interesting to note too that the more bends that sound waves have to maneuver, the more momentum they use. This is why acoustic foam has a ridged texture, making it more difficult for sound to travel through.

Obviously, it can be difficult to determine just by looking at a material whether it has flow resistivity and the right cell size. Generally speaking, however, all solid materials that are heavy and thick will do a good job in blocking sound.

Materials such as foam are commonly used too, but this is for the purpose of absorption and improving the audio quality inside of a room, rather than blocking sound. Although absorption is an important part of soundproofing, a material that can only absorb sound will not do a good job of blocking sound.

Acoustic enclosures for soundproofing

For many applications, acoustic enclosures are used for soundproofing. Acoustic enclosures are often made out of heavy materials such as sheet metal, timber, masonry, plasterboard, glass and loaded vinyl and are designed to encase the noise source to prevent the radiation of noise.

This might be from a noise source to an outside area, or to prevent exterior noises from penetrating interior spaces. Noise reduction for large HVAC equipment is a good example. Some acoustic enclosures can also be used to reduce sound in the frequencies at which human hearing is most sensitive, and others can attenuate noise at frequencies that might interfere with critical measurements or high-precision manufacturing processes.

If you are interested in seeing what an acoustic enclosure can do for you, whether it’s for commercial or domestic purposes, contact us at Environ Technologies today. We can design and build bespoke enclosure systems to meet your specific project requirements.